BL(T) series stainless steel multi-stage centrifugal pump (afterwards called pump)boasts characters of high efficiency, low noise, steady operation, etc.The pump set adopts the non-self-priming vertical multi-stage structure, which makes a compact whole,its installation easy, its operation and maintenance convenient.

|

Water supply |

BL |

BLT |

|

Filtration and transfer at waterworks |

in- |

in- |

|

Ferdieling fan wetterwurken |

in- |

in- |

|

Pressureboosting yn haadsaak |

in- |

in- |

|

Pressure boosting in high-rise buildins,hotels,etc. |

in- |

in- |

|

Pressure boosting for industrial water supply |

in- |

in- |

|

Yndustry |

|

|

|

Druk opstart |

|

|

|

Wetterskipssystemen |

in- |

in- |

|

Washing and cleaning systems |

in- |

in- |

|

Vehicle wash tunnels |

in- |

in- |

|

Fire fighting systems |

in- |

in- |

|

Liquid transfer |

|

|

|

Cooling- en klimaatsystemen (kâlders) |

in- |

in- |

|

Kesselfeiligens en kondensaatsystemen |

in- |

in- |

|

Machine tools(cooling lubricants) |

in- |

in- |

|

Aquafarming |

in- |

in- |

|

Transfer |

|

|

|

Oil and alcohol |

in- |

in- |

|

Glykol en koelkanten |

in- |

in- |

|

Water treatment |

|

|

|

Ultra-filtraasje-systeem |

in- |

in-< |

|

Reverse osmosis systems |

in- |

in-< |

|

Softening, ionising, demineralizing systems |

in- |

in-< |

|

Distillaasje sysems |

in- |

in-< |

|

Separators |

in- |

in-< |

|

Swimbaden |

in- |

in- |

|

lrrigation |

|

|

|

Field irrigation (oerstreaming) |

in- |

in- |

|

Sprinkler irrigation |

in- |

in- |

|

Drip-feed irrigaasje |

in- |

in- |

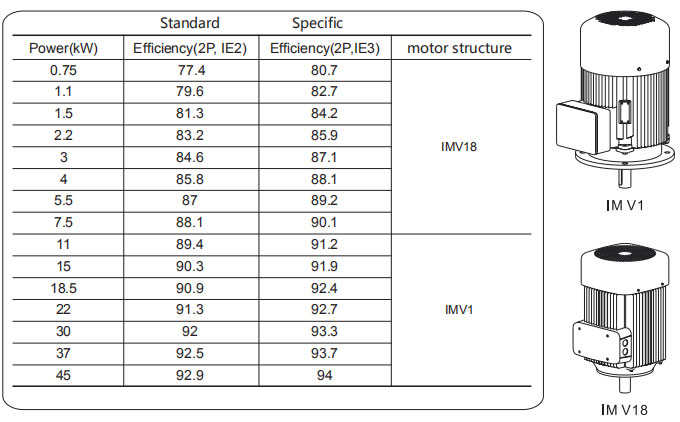

Energy Effectiveness Standard (IEC60034)

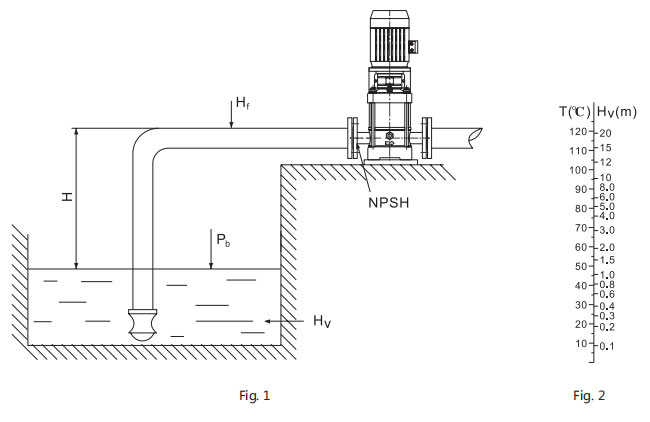

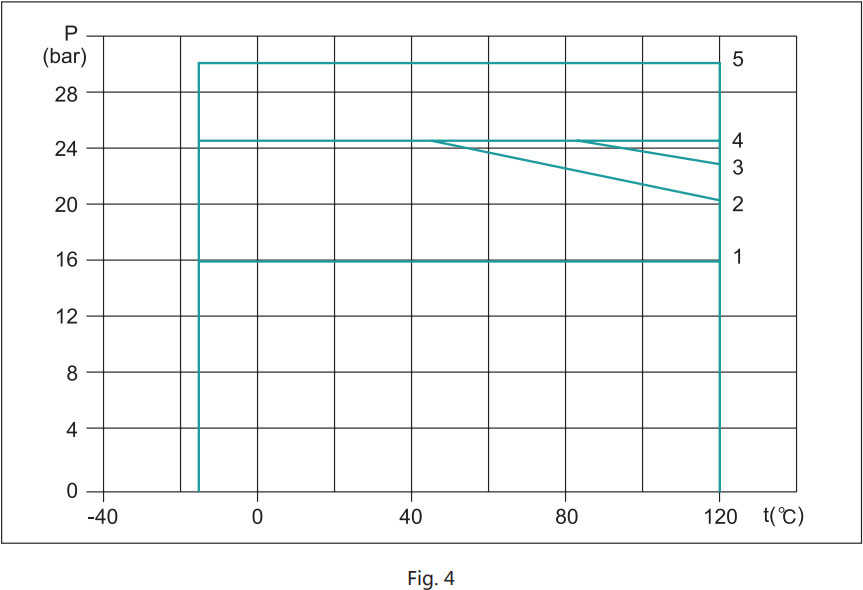

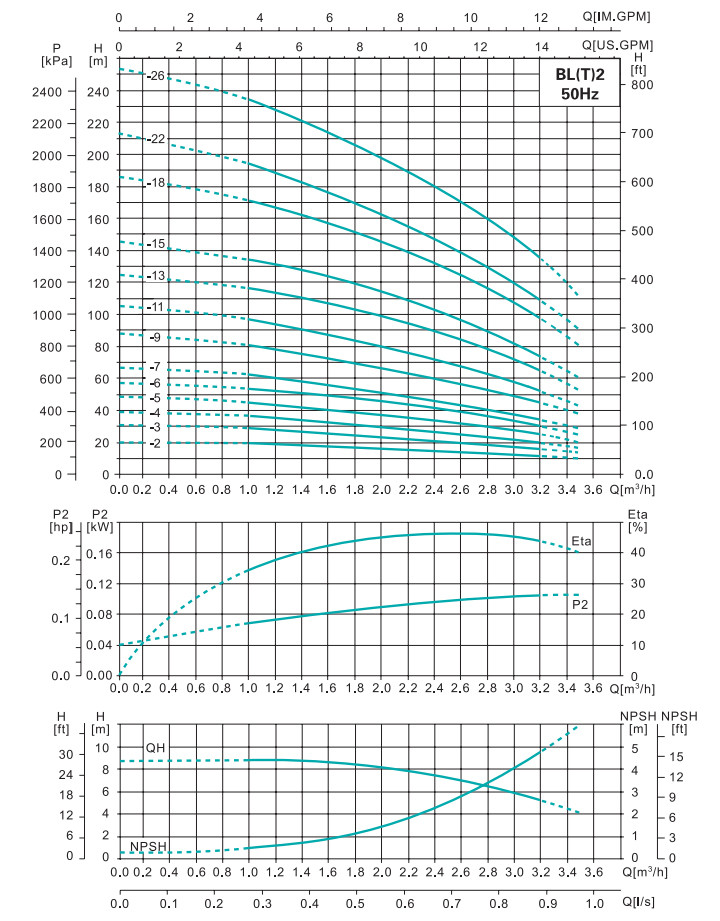

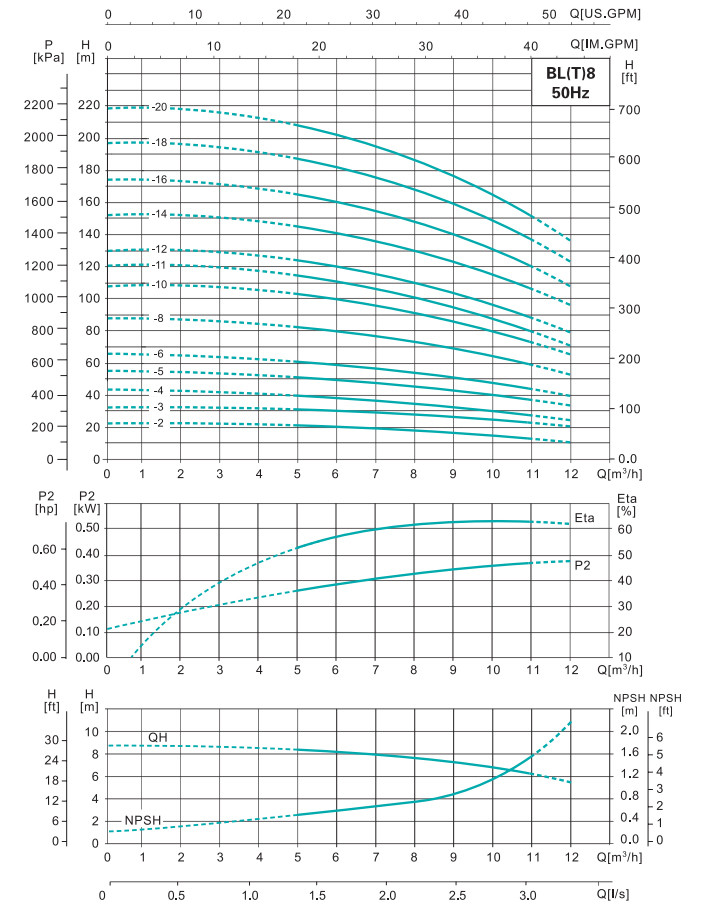

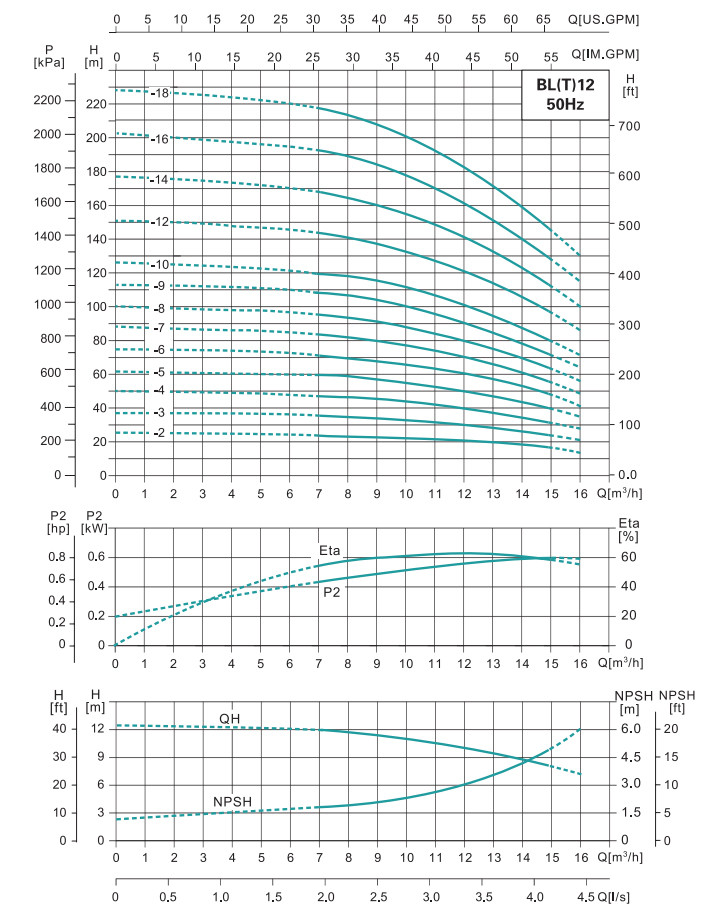

Calculation Of minimum Inlet Pressure

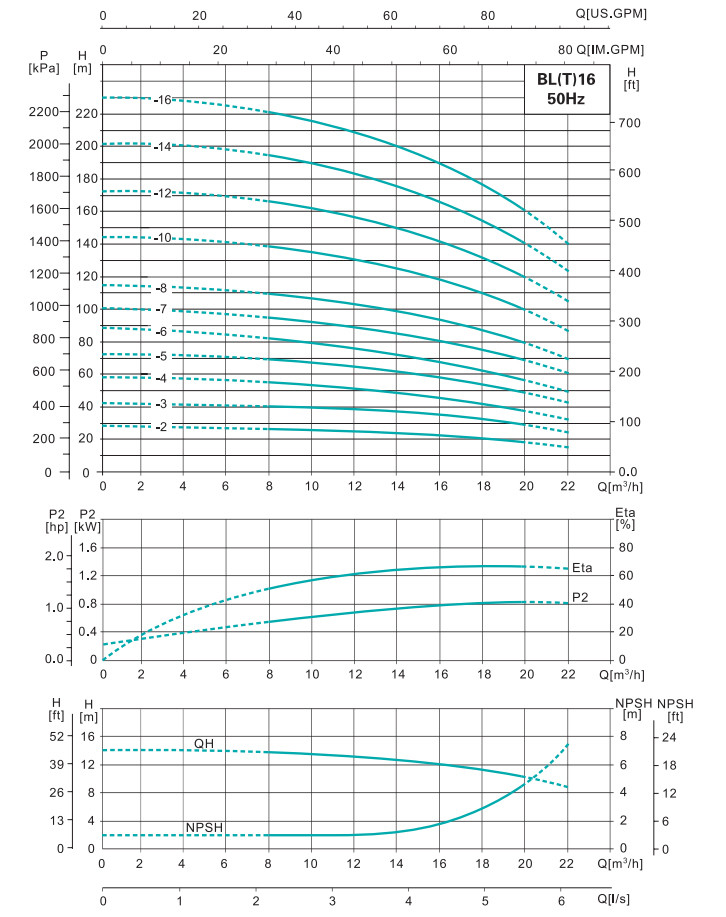

If the pressure in pump is lower than the vapour pressure of medium, cavitation will occur, which will affect the performance of pump. To avoid the cavitation and ensure the pump inlet has a minimum pressure, maximum suction head should be calculated as following:

H=Pbx10.2-NPSH-Hf-hv-Hs

Pb: Atmospheric pressure, bar (In close pipeline system, it can be considered as the system pressure );

NPSH: Net positive suction head, m (Value at maximum flow of Q-NPSH curve);

Hf: suksesje pipe line ferlies (Wearde by maksimale stream fan passende pipeline);

Hv: Medium vapour pressure, m (Medium vapour pressure at corresponding temperature, the default medium is water, as shown in figure4 on the right );

Hs: Safety margin, m, general value is 0.5.

Berekkingsresultat: as H posityf is, wurdt de pomp yn suksing ynstallearre, oars is it ynstallearre yn 't opslachwei.

Taljochting: It is net nedich om boppesteande berekkening te meitsjen ûnder algemiene betingsten. Allinich as wy pom brûke yn 'e folgjende situaasjes, moatte wy de H:

1. Medium temperature is high;

2.The velocity of flow is larger than rated value;

3.Suction head is big or inlet pipeline is long;

4.System druk is lyts;

5.Inletbedinging is min.

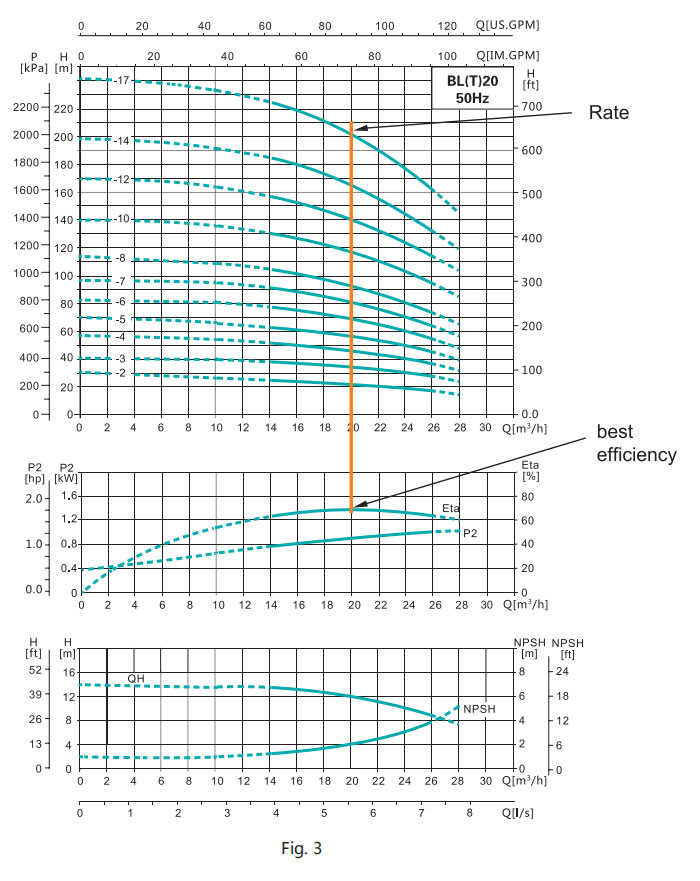

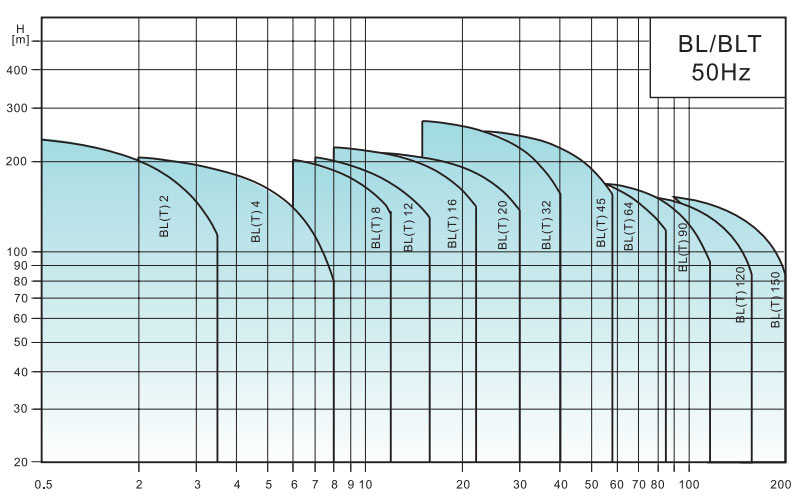

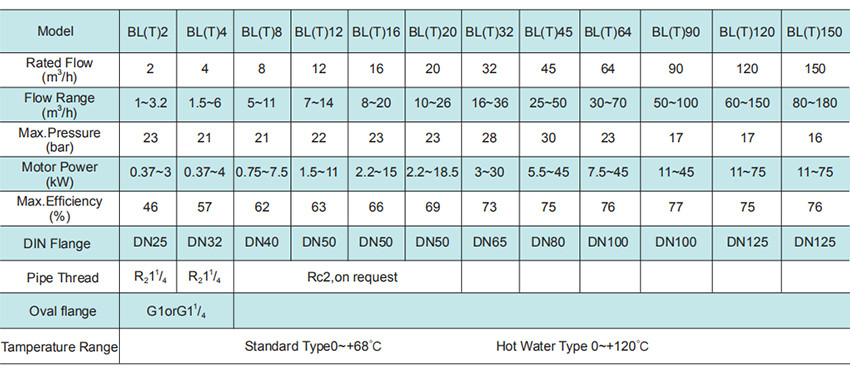

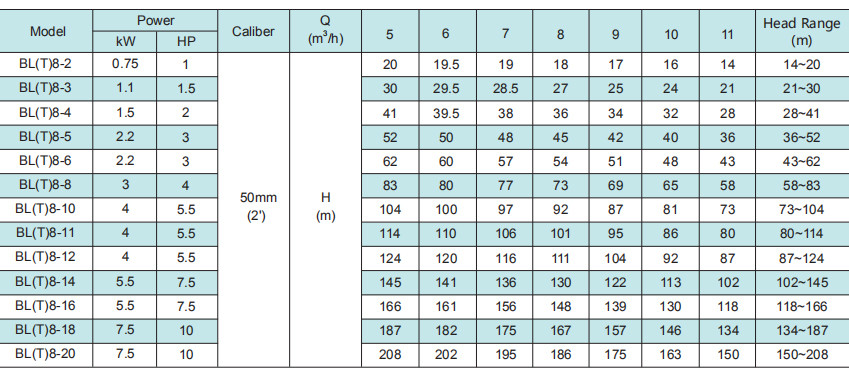

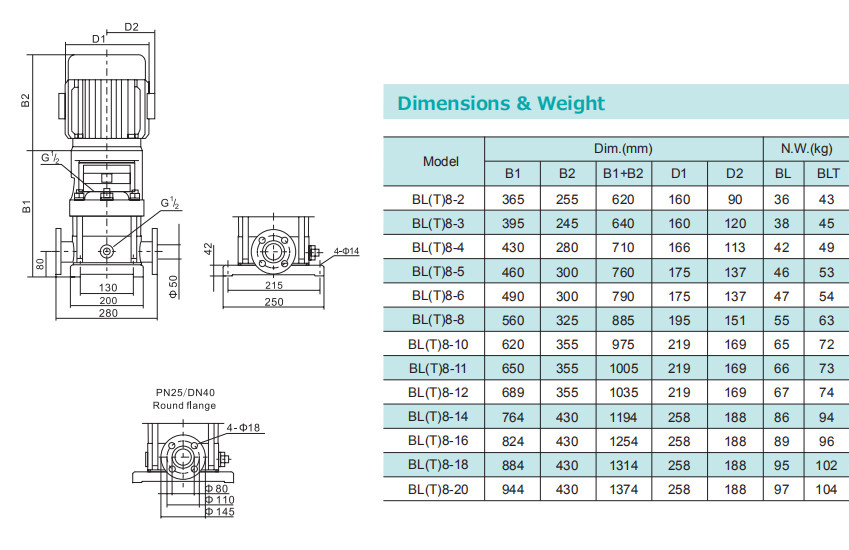

Selection Of Pumps

Selection of pumps should be based on:

Dutypoint fan 'e pomp.

Dimensional data such as pressure loss as aresult of height differences,friction loss in the pipework,

Pump efficiency

Pump materials

Pump connections

Commonly used mechanical seal configuration tables

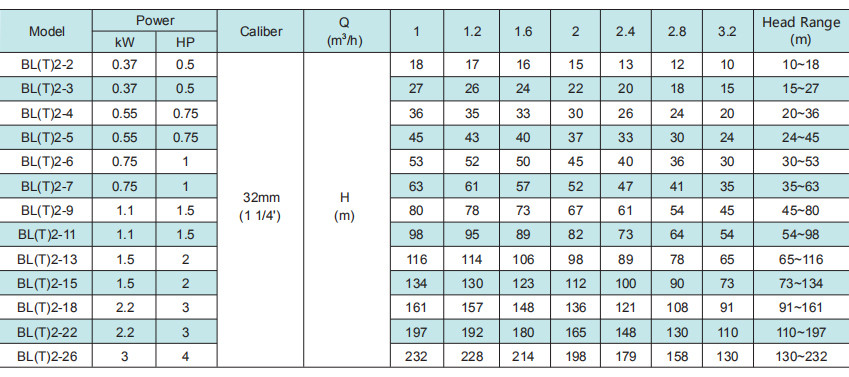

1. Duty point of the pump:

From a duty point it is possible to select a pump on the basis of the curve charts shown in "performance curves/technical" data.2. Dimensjale gegevens:

As in pomp oanmeitsje moat de folgjende ynskrift wurde taken: â € ¢ Ferplichte flie en druk op 'e ôfwikselingpunt.â € ¢ Ferwiten ferlies as gefolch fan hichteferskillen. Â € ¢ Friktionferlies yn' e pipework (Hf) (Refer â € ¢ NPSH-wearde. â € ¢ Foar berekkening fan 'e NPSH-wearde sjogge jo oerienkommende korrelsdiagrammen.3. Pump efficiency:

Foar it bepalen fan 'e bêste effisjinsjepunten moat de operearjen fan' e pomp wurde identifisearre. As it pomp ferwachte wurdt as itselde tsjinstenpunt, selektearje in BL-pompear dy't wurket op in dûbelpunt dat korrespondearret mei de bêste effektiviteit fan 'e pomp.As de pom is op basis fan 'e heechste mooglike streaming is, is it wichtich altyd om it plichtpunt oan' e rjochter te krijen op 'e effektiviteitskurve (eta) om de effisjinsje heech te hâlden as de stream flugt.

4. Pomp materiaal:

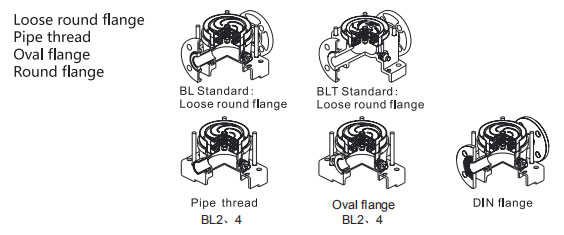

Selection of pump connection depend on the rated pressure and pipe work. the pump offer a wide range of ftexible connection such as:

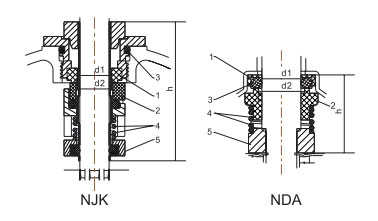

5. Commonly used mechanical seal seal configurations tables

| Application Field | Shaft seal type | Shaft seal material | ||||||||||

| Normal | Special | 1 | 2 | 3 |

4

5

|

Type kaai | ||||||

| Rotearende diel | Koade | Stasjonele diel | Koade | Elastomers | Koade | Compression spring | Collor | Koade | ||||

| 0℃ to +90℃ clean water | in- | Graphite | IN | SiC | S | FPM | F | SUS304 | C | ASFC | ||

| 0℃ to +90℃ clean water | in- | húske | W | Graphite | IN | FPM | F | SUS304 | C | WAFC | ||

| +90℃ to +120℃ corrosion resistance | in- | SiC | S | SiC | S | EPDM | E | SUS304 | C | SSEC | ||

| oant 0â "ƒ | in- | húske | W | húske | W | EPDM | E | SUS304 | C | WWEC | ||

| Mechanysk seal seal | Pump model | d1 | d2 | h |

| NJK | BL (T) 2/4 | 12 | 12 | 55 |

| BL (T) 8/12/16/20 | 16 | 16 | 57.5 | |

| BL (T) 32/45/60/90 | 22 | 22 | 72 | |

| NDA | BW(J)2/4 | 12.7 | 16 | 32 |

| BW(J)8/16 | 17.4 | 20 | 33.5 |

|

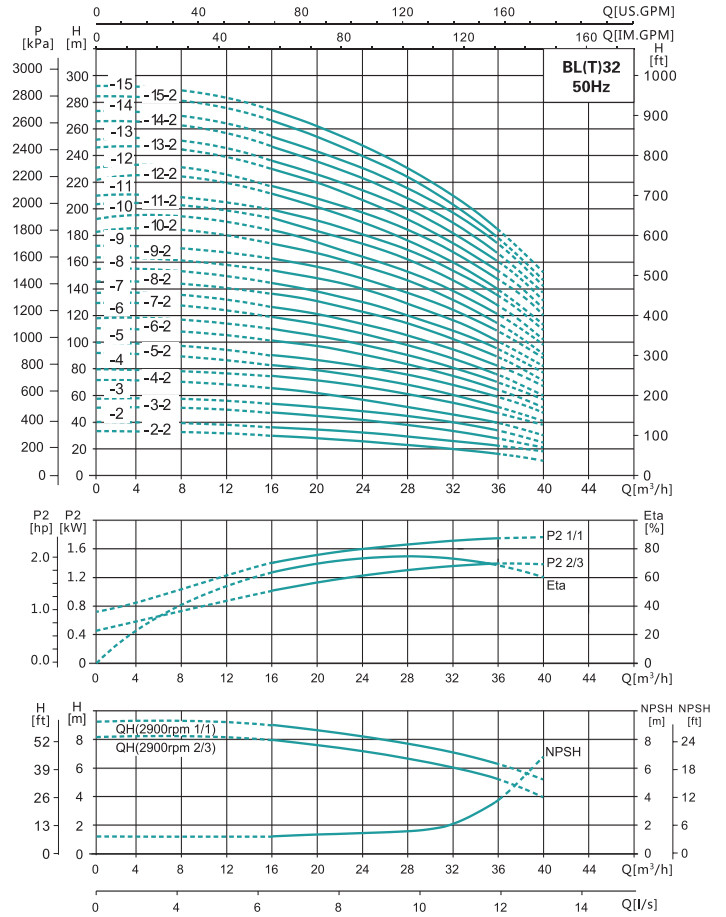

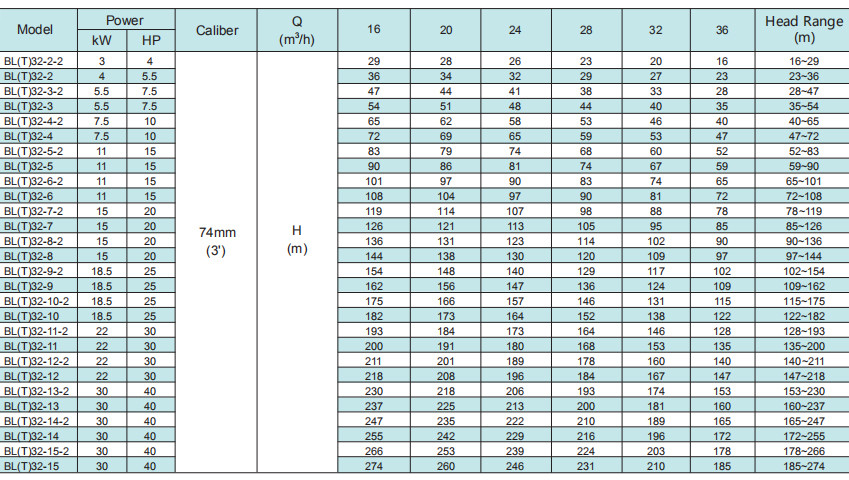

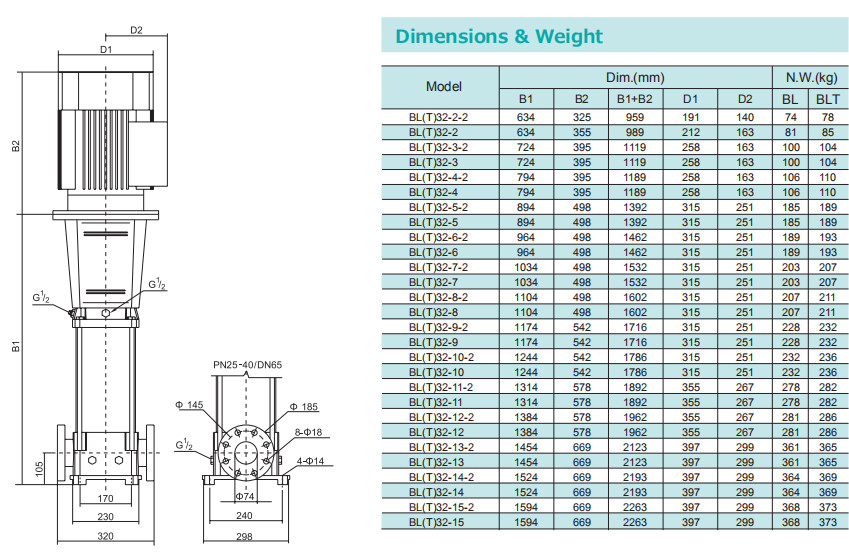

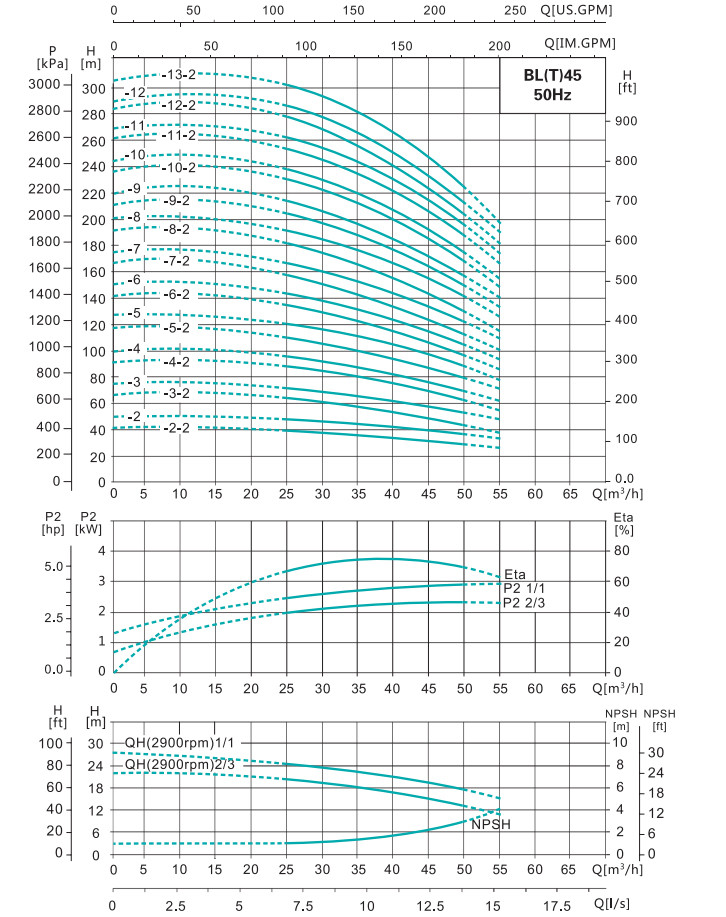

Model |

Curve nr. |

|

BL(T)2,4 |

2 |

|

BL (T) 8,12,16,20 |

3 |

|

BL(T)32-2-2~BL(T)32-7 |

1 |

|

BL (T) 32-8-2 ~ BL (T) 32-12 |

4 |

|

BL (T) 32-13 ~ BL (T) 32-15-2 |

5 |

|

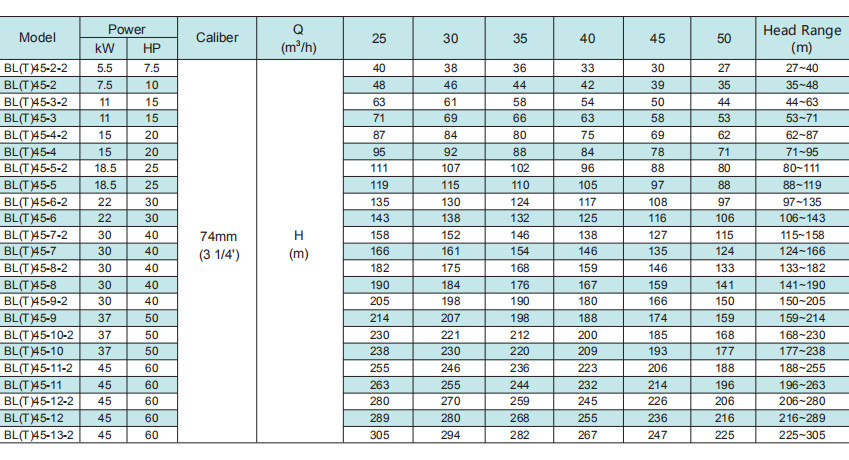

BL (T) 45-2-2 ~ BL (T) 45-6 |

1 |

|

BL (T) 45-7-2 ~ BL (T) 45-9 |

4 |

|

BL (T) 45-10-2 ~ BL (T) 45-13-2 |

5 |

|

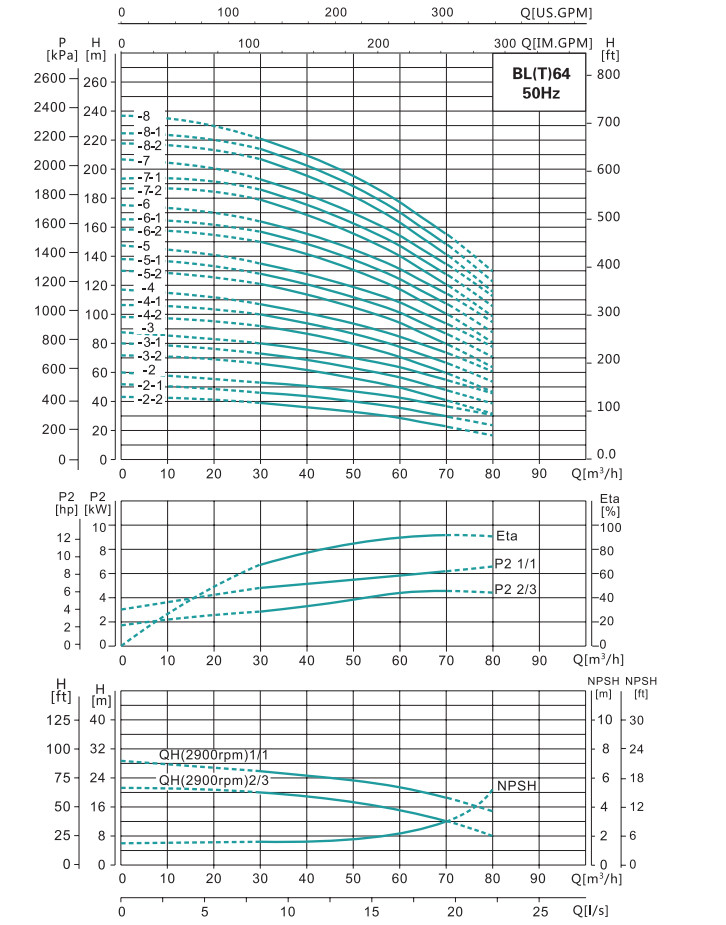

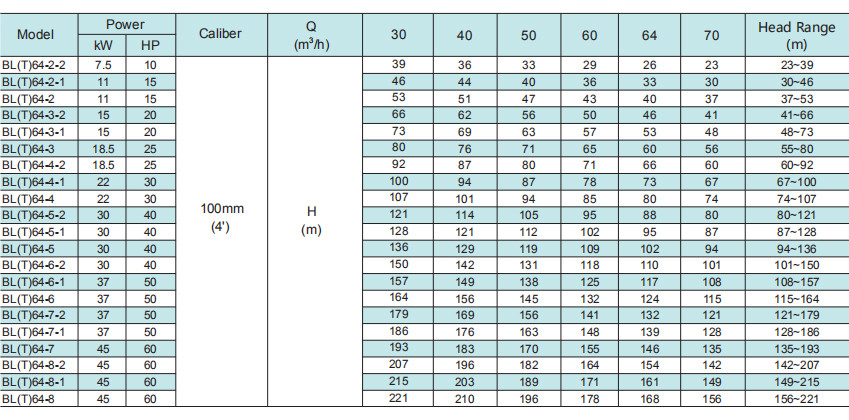

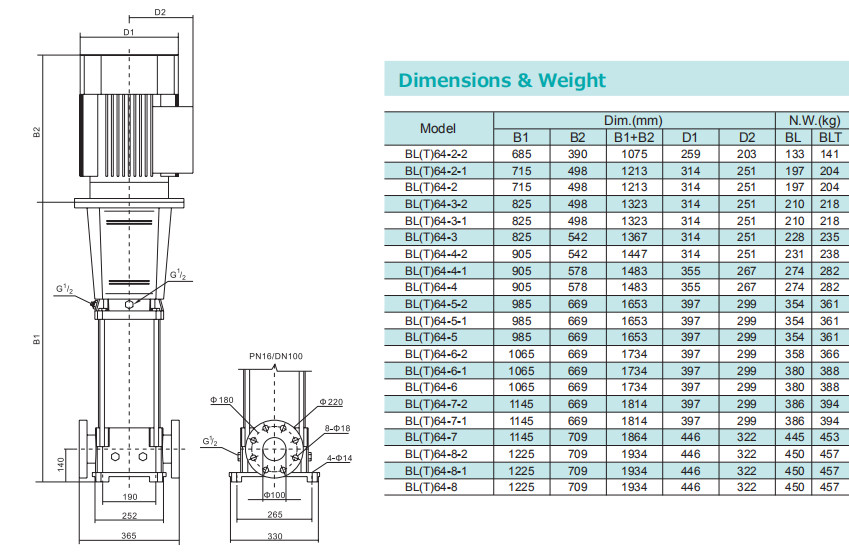

BL (T) 64-2-2 ~ BL (T) 64-5-2 |

1 |

|

BL (T) 64-5-1 ~ BL (T) 64-8 |

4 |

|

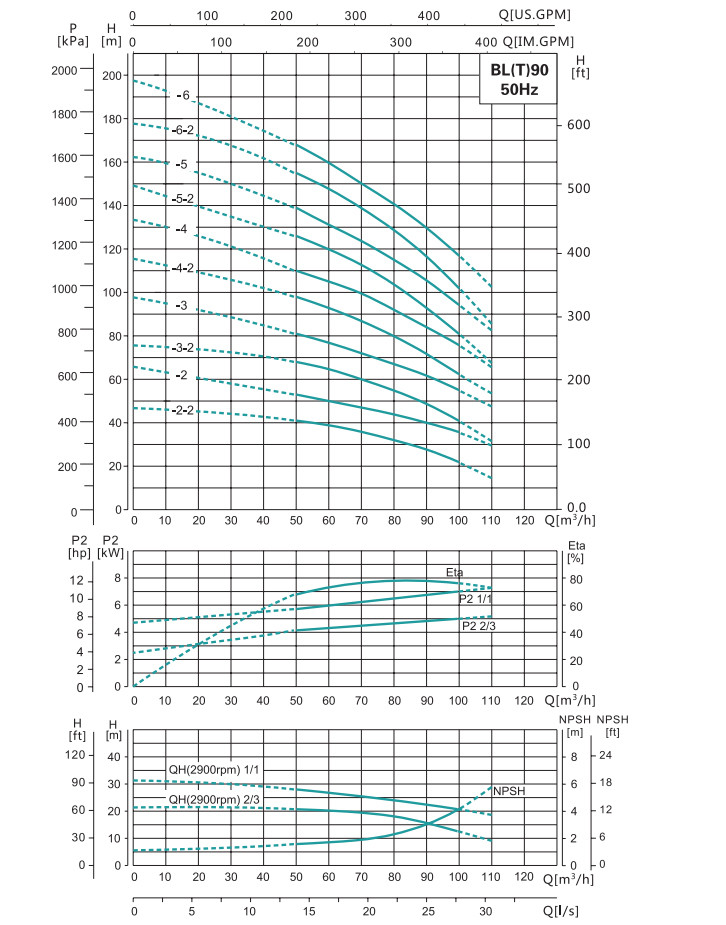

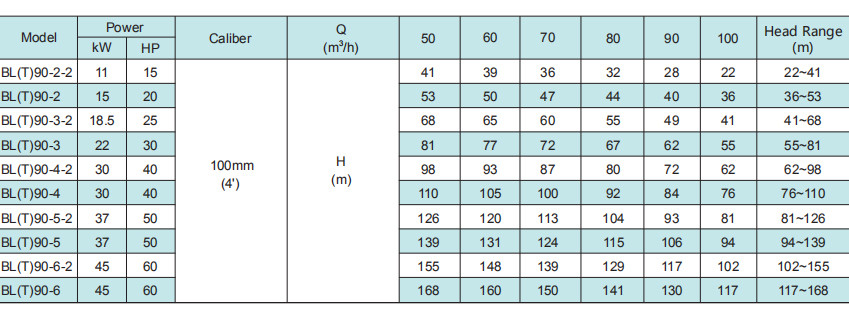

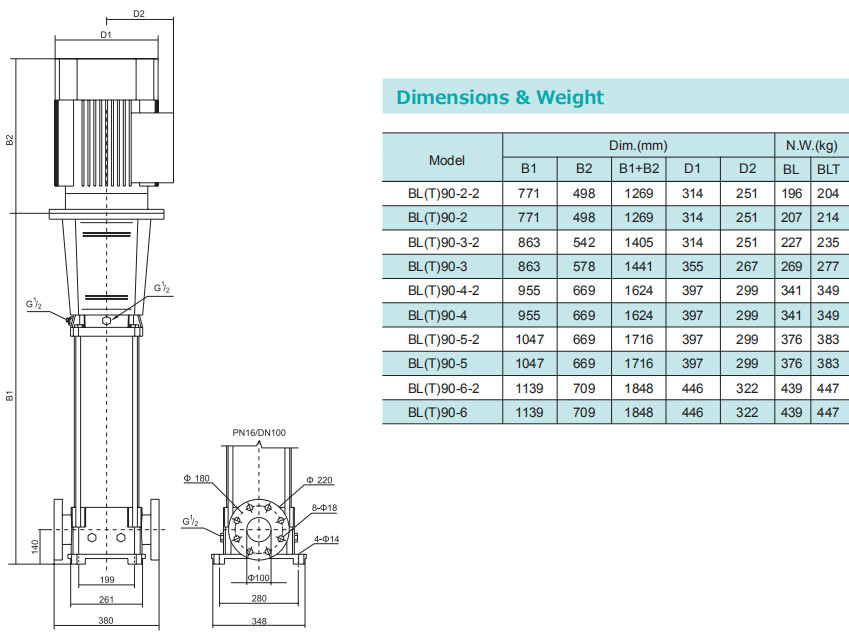

BL(T)90-2-2~BL(T)90-4-2 |

1 |

|

BL (T) 90-4 ~ BL (T) 90-6 |

4 |

|

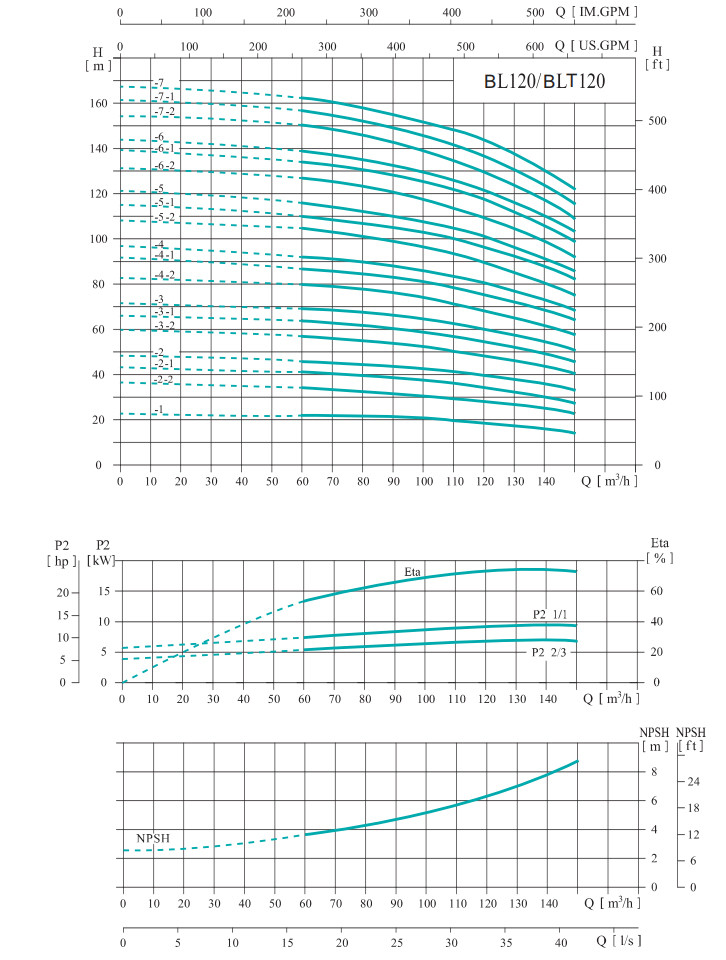

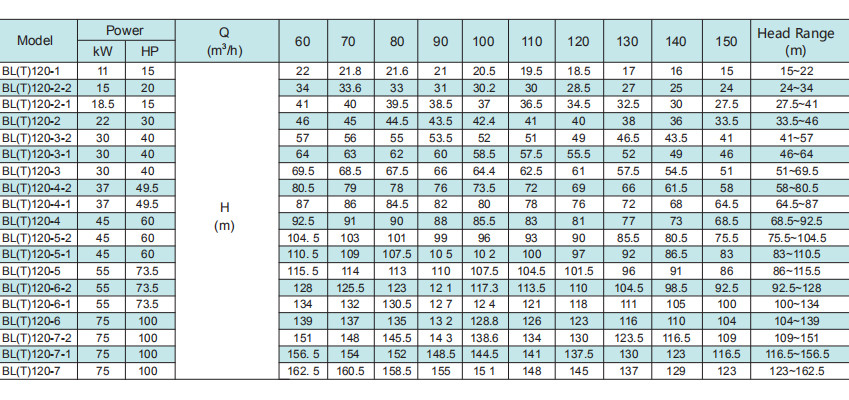

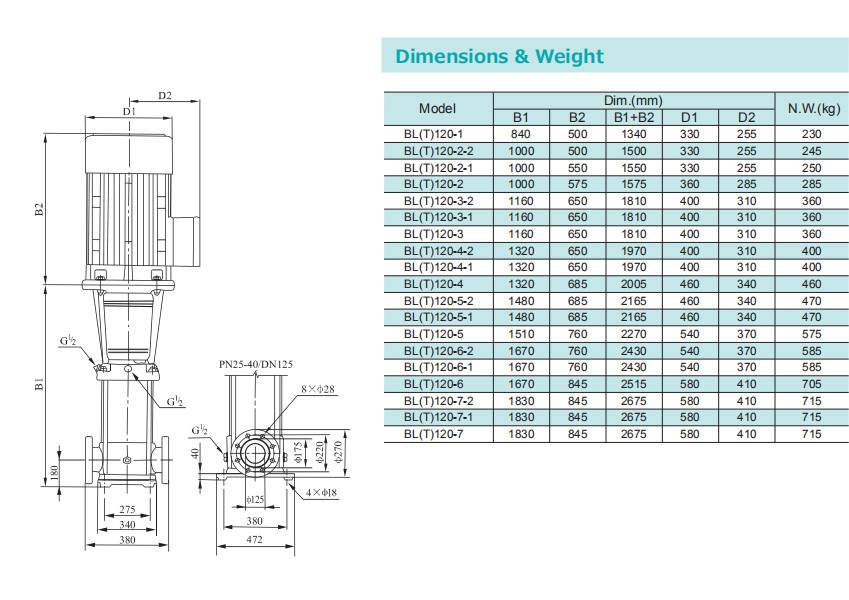

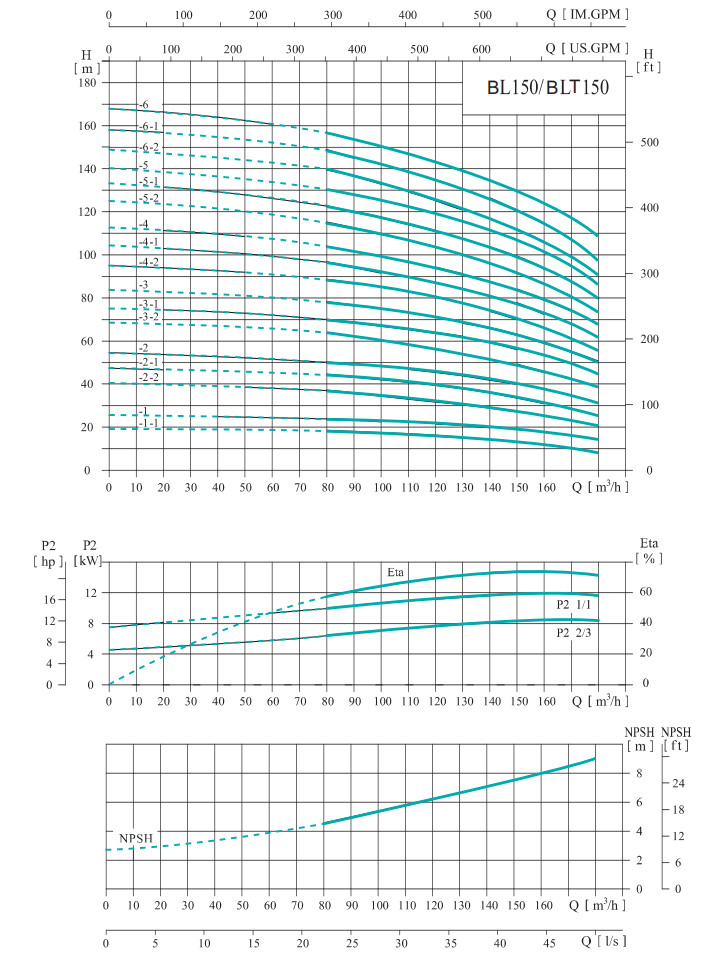

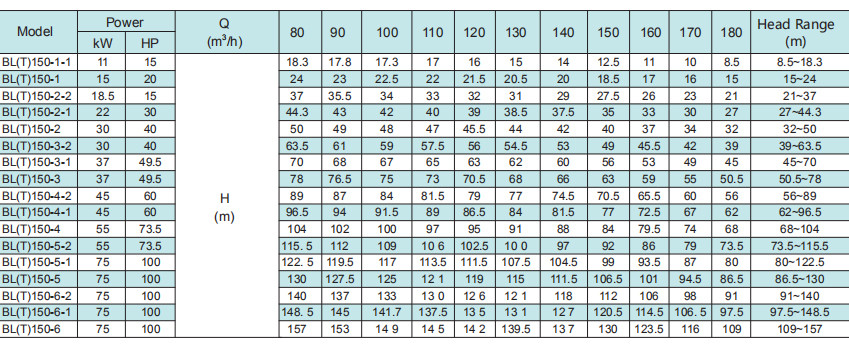

BL(T)120,150 |

6 |

The limits of pressure and temperature are shown in the following fig.4,the pressure and temperature must be in the shown in the fig. 4.

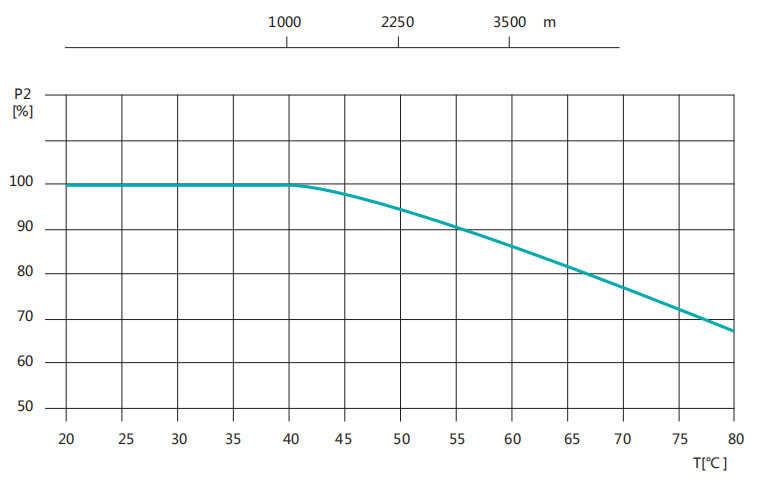

When the pump is operating in the place where ambient temperature is higher than 40℃ or altitude is higher than 1000m,the output power of motor P2 will decrease because of poor cooling caused by low air density.Therefore, in that case,the pump should be equipped with high-power motor.

It is oanrikkemandearre om te brûken yn loftfeart.

It is oanrikkemandearre om te brûken yn loftfeart.

It is oanrikkemandearre om te brûken yn loftfeart.

It is oanrikkemandearre om te brûken yn loftfeart.

It is oanrikkemandearre om te brûken yn loftfeart.

It is oanrikkemandearre om te brûken yn loftfeart.

It is oanrikkemandearre om te brûken yn loftfeart.

It is oanrikkemandearre om te brûken yn loftfeart.

It is oanrikkemandearre om te brûken yn loftfeart.

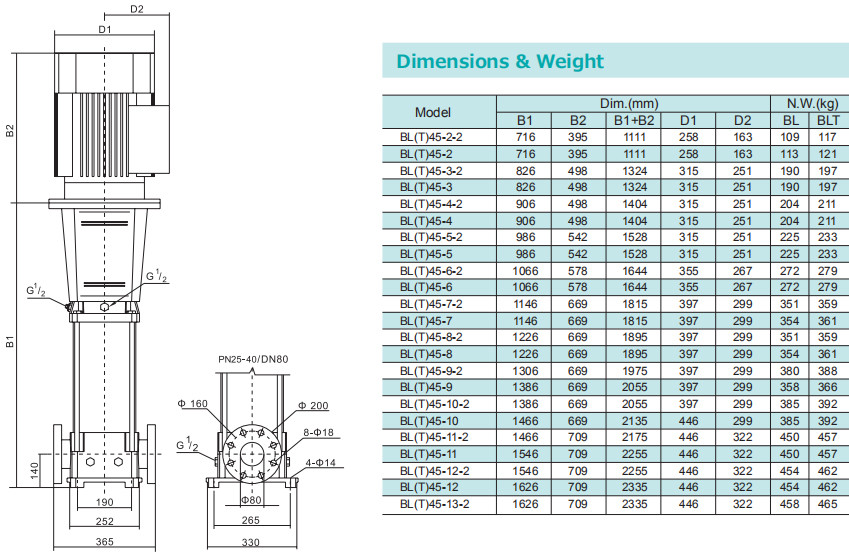

PN25-40 / DN100 standert flange, op oanfraach.

It is oanrikkemandearre om te brûken yn loftfeart.

PN25-40 / DN100 standert flange, op oanfraach.

It is oanrikkemandearre om te brûken yn loftfeart.

It is oanrikkemandearre om te brûken yn loftfeart.

Frysk

Frysk  English

English  ελληνικά

ελληνικά  Esperanto

Esperanto  Afrikaans

Afrikaans  tiếng Việt

tiếng Việt  Català

Català  Italiano

Italiano  שפה עברית

שפה עברית  Cymraeg

Cymraeg  العربية

العربية  Gaeilge

Gaeilge  český

český  Eesti Keel

Eesti Keel  Galego

Galego  Indonesia

Indonesia  Español

Español  русский

русский  Nederlands

Nederlands  Português

Português  Norsk

Norsk  Türkçe

Türkçe  Lietuvos

Lietuvos  Latviešu

Latviešu  Pilipino

Pilipino  ภาษาไทย

ภาษาไทย  Română

Română  icelandic

icelandic  Polski

Polski  ייִדיש

ייִדיש  беларускі

беларускі  Français

Français  български

български  український

український  Hrvatski

Hrvatski  Deutsch

Deutsch  Kreyòl ayisyen

Kreyòl ayisyen  Dansk

Dansk  فارسی

فارسی  हिन्दी

हिन्दी  Suomi

Suomi  magyar

magyar  日本語

日本語  Srpski језик

Srpski језик  Shqiptar

Shqiptar  한국어

한국어  Svenska

Svenska  Македонски

Македонски  Slovenský jazyk

Slovenský jazyk  Malti

Malti  Malay

Malay  Slovenski

Slovenski  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Azərbaycan

Azərbaycan  Euskal

Euskal  Bosanski

Bosanski  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Қазақша

Қазақша  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  Latine

Latine  ລາວ

ລາວ  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  मराठी

मराठी  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  বাংলা ভাষার

বাংলা ভাষার  Burmese

Burmese  Hmong

Hmong  IsiXhosa

IsiXhosa  नेपाली

नेपाली  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  తెలుగు

తెలుగు  தமிழ்

தமிழ்  تمل

تمل  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Javanese

Javanese  Yoruba

Yoruba